Machine Profile

Line Features

Videolar

Broşürler

PVC

Where your way meets with compound

With DCOMP-P, PVC compounds can be produced in soft or rigid form of PVC powder mixture previously mixed in the mixer. With DCOMP-P, it is possible to produce rigid PVC compounds as well as cable components such as fillers, sheaths, insulation and roving, gasket compounds.

Self-cleaning Screw

Self-cleaning screw design prevents formation of dead zones and stagnat points and provides maximum production quality.

- Co-rotating twin screw desing

- 1 main feeding unit

- Side feeding unit

- Gravimetric Feeders (Loss-in-Weight)

- Powerful and durable transmission

- Wear-resistant, long-lasting screw and barrel liner material

- Modular screw and barrel design

Self-Cleaning Screw

Self-cleaning screw design prevents formation of dead zones and stagnat points and provides maximum production quality.

DCOMP-P SERIES, PVC Production Capacities

| Screw Diameter (mm) |

Main Motor Power (kW) |

Max. Screw Velocity (rpm) |

Capacity (Kg/h) |

|---|---|---|---|

| 62 | 115 | 600 | 500-1000 |

| 74 | 160 | 600 | 900-1500 |

| 92 | 315 | 600 | 1500-3500 |

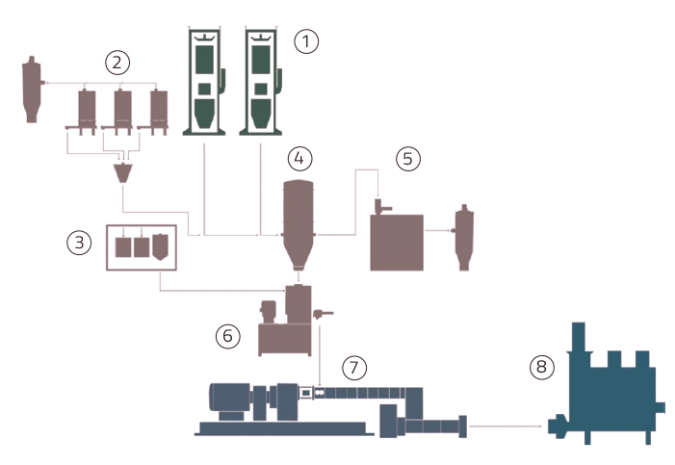

DCOMP-P

1. Big-Bag Discharger

2. Micro Dosing

3. Liquid Dosing

4. Main Weighing

5. Vacuum Blower

6. Mixer

7. DCOMP - P

8. Pellet Cooling

Feeding Unit

- Co-rotating main and side feeders

- Equipped with vibration and mixing motors

Palletizing Unit

- Die-plate cutting

- Adjustable cutter speed

Torque Limitter

- Equipped with overload protection for torque peaks.

Barrel And Liner

- 4 L/D barrels and modular design

- Hot Isostatic Pressing (HIP) method manufacturing

- High wear resistance and long life

Hot Isostatic Pressing (HIP)

- Screw elements produced by HIP technology

- 20.000 working hours life

Modular Design

- Modular screw and barrel elements for different compounds

- Seperate heating and cooling systems for each barrel